The Internet of Things (IoT) is transforming electronics manufacturing with increased efficiency and productivity, as well as better products. Factories are installing IoT-equipped devices both to monitor and control production in real time, lowering downtime as well as reducing errors. Last year a report by Deloitte said that in electronics manufacturing the IoT has improved overall equipment effectiveness (OEE) 10-20 %. Embedded in machines, the sensors are collecting data to enable predictive maintenance, improving the use of resources, and preventing equipment from failing. This data-driven approach is allowing manufacturers to make informed decisions, optimize their supply chains, and meet just-in-time production. Let us analyse how the integration of IoT is pushing electronics manufacturing into a connected, agile, and intelligent future.

“For specific premises, the firm can remotely monitor the complete operation using a full-fledged building management system embedded into the MEP system. Wherever possible, the company incorporates next-generation innovative technologies, be it demand-based ventilation or IoT solutions for air conditioning and elevators,” says Chinthake Kodippilikande, CEO, of Abans Engineering.

IoT in electronics manufacturing significantly boosts operational efficiency across the production chain. The role of IoT-enabled devices and sensors is to gather real-time data, analyse it, and assist in decisions. This optimizes the manufacturing procedure in many ways.

Sensors in manufacturing gear, enabled by IoT, collect temperature, vibration, and usage data. Using this data with advanced analytics helps manufacturers predict machine breakdowns. Then, they can schedule necessary maintenance ahead of time. This reduces downtime, cuts maintenance costs, and lengthens the life of equipment.

For example, a top Electronics manufacturer used IoT sensors for predictive maintenance on assembly lines. The sensors monitor machine health, helping spot potential problems early. This led to a 30% decrease in machine downtime and a significant boost in productivity.

“Data, in today’s world, plays a vital role here. Upgrading legacy systems and leveraging data analytics and AI identifies bottlenecks, predicts maintenance needs, and fine-tunes production. Extending data beyond factory gates optimizes core manufacturing processes by improving planning and resource utilization.” says Sanjiv Chatterjee, Head of Supply Chain- Africa, Middle East, and Turkey (AMET) - LIPTON Teas and Infusions.

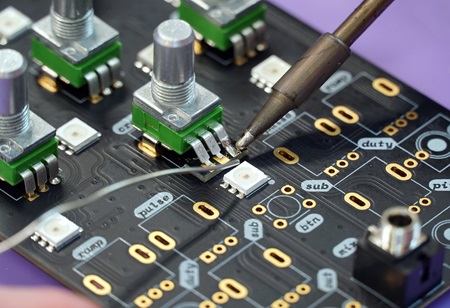

IoT is critical in improving how we check and assure quality in electronics. It lets us watch and study data in real-time. This way, we can find mistakes and problems early, making sure only top-notch products are sold. Old school ways of checking quality took too much time and had room for human error. IoT brings in snappy checking systems. These systems use cameras, sensors, and learning programs to check goods with extreme accuracy.

Imagine a big electronics company. They decided to add a clever checking process to their assembly line. They put cameras and sensors in just the right places. These gadgets took super detailed photos of every piece they made. Then, the company taught computer programs to point out problems or weird things in the images. This created a big difference. There were fewer mistakes, and the quality of their goods improved by 40%. The company saved money they might have spent fixing errors or doing things again. Plus, people started trusting their products even more than before.

IoT is shaking up the method electronics makers organize their supply chains. It brings openness, the ability to trace, and skill. Linking up the different parts of the supply chain, running from raw material providers to those who distribute, IoT gives the power of instant watching and making things better. This leads to cost-cutting and a boost in overall productivity.

The ability to manage stock well is critical to making electronics. Here's where IoT steps in and becomes essential. It brings life and a reaction to this process. Sensors on storage racks and bins always keep an eye on stock levels. They deliver real-time details to those who make and supply.

Worldwide parts suppliers for electronics started using instant inventory handling with IoT. They used sensors and RFID tech to track part movement in their warehouses. This enabled improved demand prediction, decreased the chance of running out of inventory, and streamlined the entire supply flow. This allowed the business to slash inventory costs by 20%, enhancing the successful fulfilment rate.

“With advanced analytics and machine learning algorithms now, companies can analyse historical sales data, market trends, and customer behavior to make more accurate demand forecasts. Thereby leading a better inventory planning and optimization. By deploying IoT devices and sensors across inventory, companies are now able to track items throughout the supply chain,” says Denis Caes, Director, Scoular.

IoT is now part of electronic production. It is bringing a new wave of good results. With advancing tech, IoT will further change how we make electronics. Companies that use IoT can get ahead. This is not only because it can save money but also because it can make better products for a picky market. We are starting to create a more innovative, joined way of making electronics. Anyone ready to make changes and be different has a lot to gain.

We use cookies to ensure you get the best experience on our website. Read more...